Air Pollution Control Systems

Dust Extraction/Collection System

Dust collection systems is used in many processes to either recover valuable granular solid or powder from process streams, or to remove granular solid pollutants from exhaust gases prior to venting to the atmosphere. Dust collection is an online process for collecting any process-generated dust from the source point on a continuous basis. Dust collectors may be of single unit construction, or a collection of devices used to separate particulate matter from the process air. They are often used as an air pollution control device to maintain or improve air quality.

Recovery of particulate matter from exhaust gas is vital for any industry from three aspect:

To ensure the operators health and safety by removing the hazardous fumes from the working area,

To avoid pollution problems,

Sturdy construction,

To increase the product quality removing fumes from the process.

Dust collection / Extraction system comprises of following:

Ducting,

LEVs / Suction hood,

Cyclone / Unit dust collector / Bag filter,

Volume control dampers / Shut off dampers at branch ducting,

Centrifugal Blowers,

Chimney.

Fume Scrubbing/Exhaust System

Scrubber systems (aka Chemical Scrubbers, Gas Scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. The first air scrubber was designed to remove carbon dioxide from the air of an early submarine, the Ictineo I, a role for which they continue to be used till today. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term has also been used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases.

Wet scrubbing: The exhaust gases of combustion may contain substances considered harmful to the environment, and the scrubber may remove or neutralize those. A wet scrubber is used for cleaning air, fuel gas or other gases of various pollutants and dust particles. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds.

Dry scrubbing:A dry or semi-dry scrubbing system, unlike the wet scrubber, does not saturate the flue gas stream that is being treated with moisture. In some cases no moisture is added, while in others only the amount of moisture that can be evaporated in the flue gas without condensing is added. Therefore, dry scrubbers generally do not have a stack steam plume or wastewater handling/disposal requirements. Dry scrubbing systems are used to remove acid gases (such as SO2 and HCl) primarily from combustion sources.

An exhaust system is usually piping used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of:

Cylinder head and exhaust manifold, A turbocharger to increase engine power., A catalytic converter to reduce air pollution.

A muffler / silencer , to reduce noise.

Odor control systems

Odor control systems are designed to reduce or completely eliminate all traces of unwanted scents within an air supply.Popular in industrial, commercial and residential applications, these systems neutralize malodors, making them unavailable for olfactory senses to pick up, thus improving air quality. Though not all odorous emissions are toxic or even physically harmful, odors that are purely unpleasant can have a negative impact on the quality of life and productivity of an area or process.

In unpleasant odor situations, it is essential that air pollution control equipment come equipped with odor control systems. These systems often mask the disagreeable smell with a stronger more pleasant scent, though this is a temporary solution. Alternatively, odor controls may neutralize them by absorbing them with specially configured powders, sprays, or filters. The latter and more permanent solution is often preferable, particularly in industrial atmospheres where smelly gasses can accumulate in large quantities.

Odor control systems are designed to reduce or completely eliminate all traces of unwanted scents within an air supply.Popular in industrial, commercial and residential applications, these systems neutralize malodors, making them unavailable for olfactory senses to pick up, thus improving air quality. Though not all odorous emissions are toxic or even physically harmful, odors that are purely unpleasant can have a negative impact on the quality of life and productivity of an area or process.

In unpleasant odor situations, it is essential that air pollution control equipment come equipped with odor control systems. These systems often mask the disagreeable smell with a stronger more pleasant scent, though this is a temporary solution. Alternatively, odor controls may neutralize them by absorbing them with specially configured powders, sprays, or filters. The latter and more permanent solution is often preferable, particularly in industrial atmospheres where smelly gasses can accumulate in large quantities.

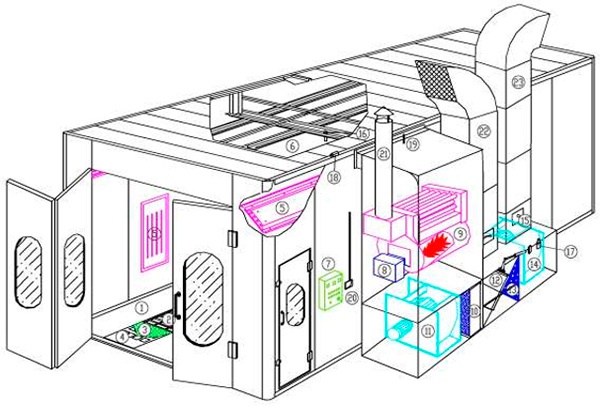

Paint shop / Painting booth with exhaust ventilation system

The exhaust system remove the paint fume laden air inside the painting zone. Dry type: spray painting booth will have filter media (paper / fabric) to eliminate the paint fume from the exhaust air. This paint booth will have filter section in the rear draft plenum.

We select the material of construction based on the MSDS of the paint. We execute total paint shop project providing required paint booths, flash off zones, conveyor, baking oven and other required material handling systems. Wet type: spray painting booth will have water screen to scrub the exhaust fume laden air before dispersing to the atmosphere. This painting booth will have internal water sump, water screen plate, water re circulating system, rear side draft section with exhaust blowers and spray painting zone. If the paint booth has to be closed one, we provide make up fresh air system as optional..

The exhaust system remove the paint fume laden air inside the painting zone. Dry type: spray painting booth will have filter media (paper / fabric) to eliminate the paint fume from the exhaust air. This paint booth will have filter section in the rear draft plenum.

We select the material of construction based on the MSDS of the paint. We execute total paint shop project providing required paint booths, flash off zones, conveyor, baking oven and other required material handling systems. Wet type: spray painting booth will have water screen to scrub the exhaust fume laden air before dispersing to the atmosphere. This painting booth will have internal water sump, water screen plate, water re circulating system, rear side draft section with exhaust blowers and spray painting zone. If the paint booth has to be closed one, we provide make up fresh air system as optional..

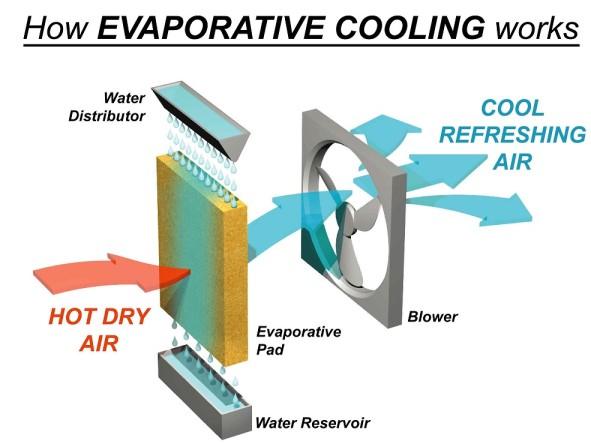

Evaporative Air Cooling

Evaporative cooling system is working with the principle that when the air is passing through water circulated cooling pad, water will be evaporated by taking the energy (heat) from the fresh dry air in an adiabatic process, due to the difference between dry bulb temperature and wet bulb temperature. Energy loses due to change water from liquid to vapour results in reduction of dry bulb temperature of air. These systems are more suitable and efficient where ambient temperature is too high & low RH levels.

Evaporative cooling system is working with the principle that when the air is passing through water circulated cooling pad, water will be evaporated by taking the energy (heat) from the fresh dry air in an adiabatic process, due to the difference between dry bulb temperature and wet bulb temperature. Energy loses due to change water from liquid to vapour results in reduction of dry bulb temperature of air. These systems are more suitable and efficient where ambient temperature is too high & low RH levels.

Evaporative cooling system include: Air inlet section, Filters, Water circulated cooling pad, Re circulation water pump with internal water sump, Blowers / Air Handing units, Ducts , Register/grills for distributing the air within the work space.

Spray Painting/ Powder Coating Booths

Spray Painting Booths with pump without pump are very popular, and widely used by a number of leading Industries all over India.Spray Painting Booths offer the following advantages over other types of conventional Booths.

The design allows for improved working environmental conditions.

The possibility of over spray fumes marring or spoiling the finish of the final products is eliminated.

The quality of the finished product is improved, for the design and construction of the Spray Painting Booths are such that while spraying, volatile fumes and any residual over spray is carried away.

The Spray Painting Booths require least maintenance for there are fewer parts that are subject to wear and tear.

The Spray Painting Booths are easy to assemble and do not occupy much space.

Spray Painting Booths with pump without pump are very popular, and widely used by a number of leading Industries all over India.Spray Painting Booths offer the following advantages over other types of conventional Booths.

The design allows for improved working environmental conditions.

The possibility of over spray fumes marring or spoiling the finish of the final products is eliminated.

The quality of the finished product is improved, for the design and construction of the Spray Painting Booths are such that while spraying, volatile fumes and any residual over spray is carried away.

The Spray Painting Booths require least maintenance for there are fewer parts that are subject to wear and tear.

The Spray Painting Booths are easy to assemble and do not occupy much space.

Air Ventilation System

We are counted among some of the most trusted names in the industry for the manufacturing and supplying a wide range of Air Ventilation System. These systems are designed as per the industrial standards in order to meet the requirement of the clients in a better way. we use supreme quality components for the assembly of these systems that assures our clients with its long serving life.

features are: Reliability, Precisely designed, Durability .

We are counted among some of the most trusted names in the industry for the manufacturing and supplying a wide range of Air Ventilation System. These systems are designed as per the industrial standards in order to meet the requirement of the clients in a better way. we use supreme quality components for the assembly of these systems that assures our clients with its long serving life.

features are: Reliability, Precisely designed, Durability .

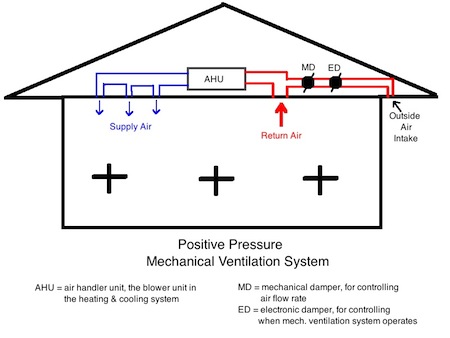

Mechanical Ventilation Systems

Generally, mechanical ventilation system is required:

To provide necessary comfort level conditions for maintaining the efficiency, health and safety of the workers.

To control hazardous concentrations of toxic materials in the indoor air.

To maintain cleanliness level of indoor air.

To maintain adequate oxygen supply in the work area.

To remove any undesirable odors from a given area.

Ventilation Design Parameters are:

Manufacturing process, Exhaust air system & local extraction, Cleanliness requirements

Ambient air conditions, Heat emissions, Contaminant emissions, Regulations.

3 main classifications: Supply air system / Pressurization system, Exhaust system, Push (supply) - Pull (Exhaust) ventilation system.

Generally, mechanical ventilation system is required:

To provide necessary comfort level conditions for maintaining the efficiency, health and safety of the workers.

To control hazardous concentrations of toxic materials in the indoor air.

To maintain cleanliness level of indoor air.

To maintain adequate oxygen supply in the work area.

To remove any undesirable odors from a given area.

Ventilation Design Parameters are:

Manufacturing process, Exhaust air system & local extraction, Cleanliness requirements

Ambient air conditions, Heat emissions, Contaminant emissions, Regulations.

3 main classifications: Supply air system / Pressurization system, Exhaust system, Push (supply) - Pull (Exhaust) ventilation system.

Humidification Plant

This is a process requirement design where humidity levels requirement is more than 60 to 70% simultaneously enhances the comfort level due to adiabatic cooling process.The outside air is filtered & allows passing through a water spray zone in the Air Handling Unit. The air leaving the water spray zone will have more moisture & this air will be distributed to the manufacturing / process area to meet their process requirement. .

This is a process requirement design where humidity levels requirement is more than 60 to 70% simultaneously enhances the comfort level due to adiabatic cooling process.The outside air is filtered & allows passing through a water spray zone in the Air Handling Unit. The air leaving the water spray zone will have more moisture & this air will be distributed to the manufacturing / process area to meet their process requirement. .

Dust Proofing / Pressurization Systems

Dust Proofing System is requirement of certain process / activities such as assembly of precision components, packing of precision products, painting process, electronic components assembly.

Dust proofing environment requirement arises -

To keep the environment as dust free zone to suit to the process / activity.

To create comfort level and more Hygienic environment for the occupants in a specified area, if the outside area is having pollutant like dust or any hazardous chemica -To meet dust proofing system, the process area is provided with filtered fresh air systems. The classification of filtration depending on the process/ equipment. To obtain dust proof zone the area need to be air tight to arrest leakage of supply air to establish positive pressure inside the area with respect to outside area or adjacent areas. The positive pressure inside will prevent dust / hazardous entry from outside.

.

Dust Proofing System is requirement of certain process / activities such as assembly of precision components, packing of precision products, painting process, electronic components assembly.

Dust proofing environment requirement arises -

To keep the environment as dust free zone to suit to the process / activity.

To create comfort level and more Hygienic environment for the occupants in a specified area, if the outside area is having pollutant like dust or any hazardous chemica -To meet dust proofing system, the process area is provided with filtered fresh air systems. The classification of filtration depending on the process/ equipment. To obtain dust proof zone the area need to be air tight to arrest leakage of supply air to establish positive pressure inside the area with respect to outside area or adjacent areas. The positive pressure inside will prevent dust / hazardous entry from outside.

.

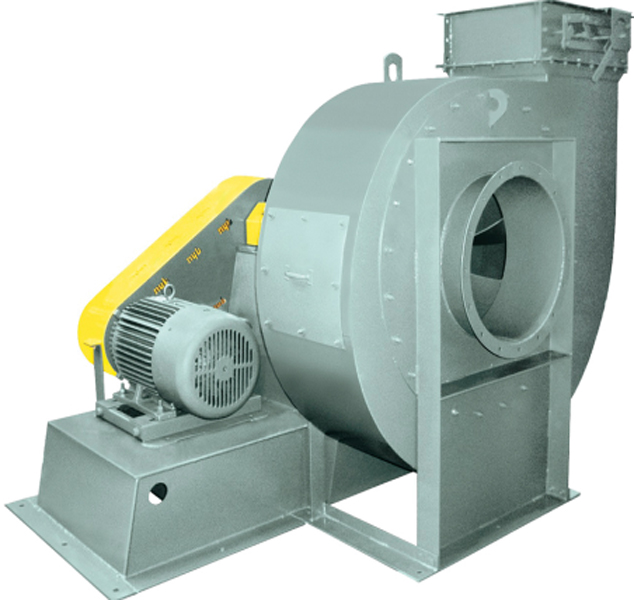

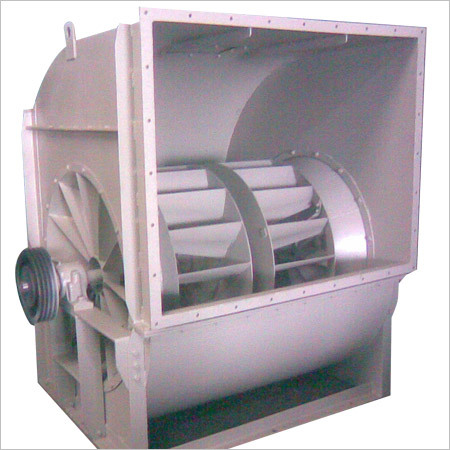

Blowers Manufactures

We provide a services of a wide range of products which include air blowers, ventilation blowers, portable blower, portable trolley mounted centrifugal blower, pp blower and pp frp centrifugal blower.

supplying superior quality Industrial Blowers. The offered blowers are manufactured using basic raw material and cutting-edge technology, under the strict supervision of our excellent engineers.Features: Optimum performance, Longer working life, Compact design

Combustion Air Blowers: Features: Optimum performance, Longer working life, Compact design..

We provide a services of a wide range of products which include air blowers, ventilation blowers, portable blower, portable trolley mounted centrifugal blower, pp blower and pp frp centrifugal blower.

supplying superior quality Industrial Blowers. The offered blowers are manufactured using basic raw material and cutting-edge technology, under the strict supervision of our excellent engineers.Features: Optimum performance, Longer working life, Compact design

Combustion Air Blowers: Features: Optimum performance, Longer working life, Compact design..

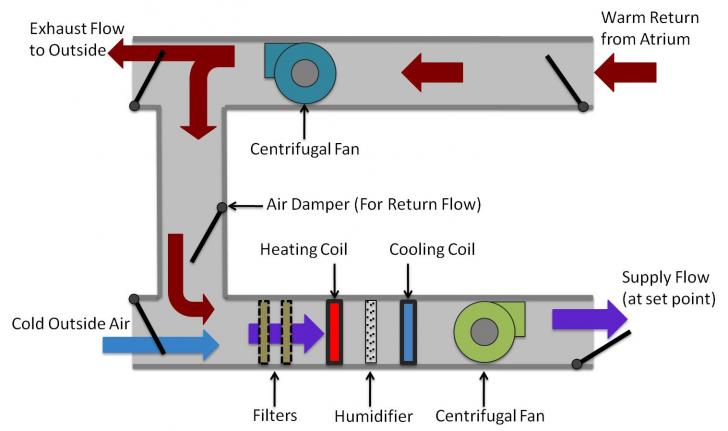

Air Handling Units

We provide excellent services Industrial Air handling equipemnts as per requiremnts. The services contains Centrifugal Fans and Blowers, Axial Flow Fans, Double Skin and Single Skin Air Handling Units, Plate Scrubber Unit , Bag Filters, Venturi Scrubber, Cyclone Separators, Unitary Dust Collectors, Packed Bed Scrubber, Wet Collectors, Roof extractors, Fume cupboards, Fire dampers, Rotary Air Lock, Spray painting booths, Butterfly Dampers & Slide Gates

We provide excellent services Industrial Air handling equipemnts as per requiremnts. The services contains Centrifugal Fans and Blowers, Axial Flow Fans, Double Skin and Single Skin Air Handling Units, Plate Scrubber Unit , Bag Filters, Venturi Scrubber, Cyclone Separators, Unitary Dust Collectors, Packed Bed Scrubber, Wet Collectors, Roof extractors, Fume cupboards, Fire dampers, Rotary Air Lock, Spray painting booths, Butterfly Dampers & Slide Gates

Clean Room

Clean room is an enclosed clean work space employing control over the particulate matter in the air with temperature, humidity and pressure control. All clean rooms must not exceed a particulate count as specified in the air.

Clean room design requirements:

Entry ways,Area to be defined to built clean room space.

Ante rooms,

Air handling system with filtration,

Air-conditioning equipment, change rooms,

Clean room furniture’s equipments, Desired level of cleanliness, Clean room lighting and fire protection.

Clean room is an enclosed clean work space employing control over the particulate matter in the air with temperature, humidity and pressure control. All clean rooms must not exceed a particulate count as specified in the air.

Clean room design requirements:

Entry ways,Area to be defined to built clean room space.

Ante rooms,

Air handling system with filtration,

Air-conditioning equipment, change rooms,

Clean room furniture’s equipments, Desired level of cleanliness, Clean room lighting and fire protection.

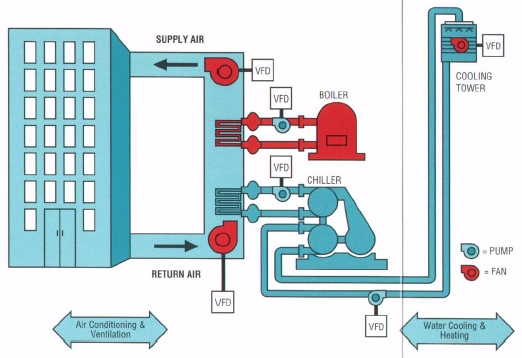

HVAC System

We provide services of HVAC. Heating, ventilation and air conditioning (HVAC) is the technology of indoor and vehicular environmental comfort. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. Refrigeration is sometimes added to the field's abbreviation as HVAC&R or HVACR, or ventilating is dropped as in HACR (such as the designation of HACR-rated circuit breakers).

HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels and senior living facilities, medium to large industrial and office buildings such as skyscrapers and hospitals, onboard vessels, and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fresh air from outdoors.

We provide services of HVAC. Heating, ventilation and air conditioning (HVAC) is the technology of indoor and vehicular environmental comfort. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. Refrigeration is sometimes added to the field's abbreviation as HVAC&R or HVACR, or ventilating is dropped as in HACR (such as the designation of HACR-rated circuit breakers).

HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels and senior living facilities, medium to large industrial and office buildings such as skyscrapers and hospitals, onboard vessels, and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fresh air from outdoors.

MN ENVIROTECH Provides excellent services in Air Pollution Control Systems: Fume Scrubbing/Exhaust System, Dust Extraction/Collection System, Paint shop / Painting booth with exhaust ventilation system, Odor control systems. Ventilation System, Blowers Manufactures, Air Handling Units, Clean Room, HVAC System and free quotations and site visit with drawing as per client requirements.

MN ENVIROTECH Provides excellent services in Air Pollution Control Systems: Fume Scrubbing/Exhaust System, Dust Extraction/Collection System, Paint shop / Painting booth with exhaust ventilation system, Odor control systems. Ventilation System, Blowers Manufactures, Air Handling Units, Clean Room, HVAC System and free quotations and site visit with drawing as per client requirements.